Information on the subject and application can be obtained from the Federal Office of Economics and Export Control: www.bafa.de

EEG § 40 ff. – EEG levy reduction

Under certain conditions companies are entitled to submit an application for a reduction in the EEG (German renewable energy act) levy.

- The company must belong to the manufacturing industry

- The electricity costs must account for at least 14 % of the gross value added

- The annual consumption must be at least 1 GWh per site

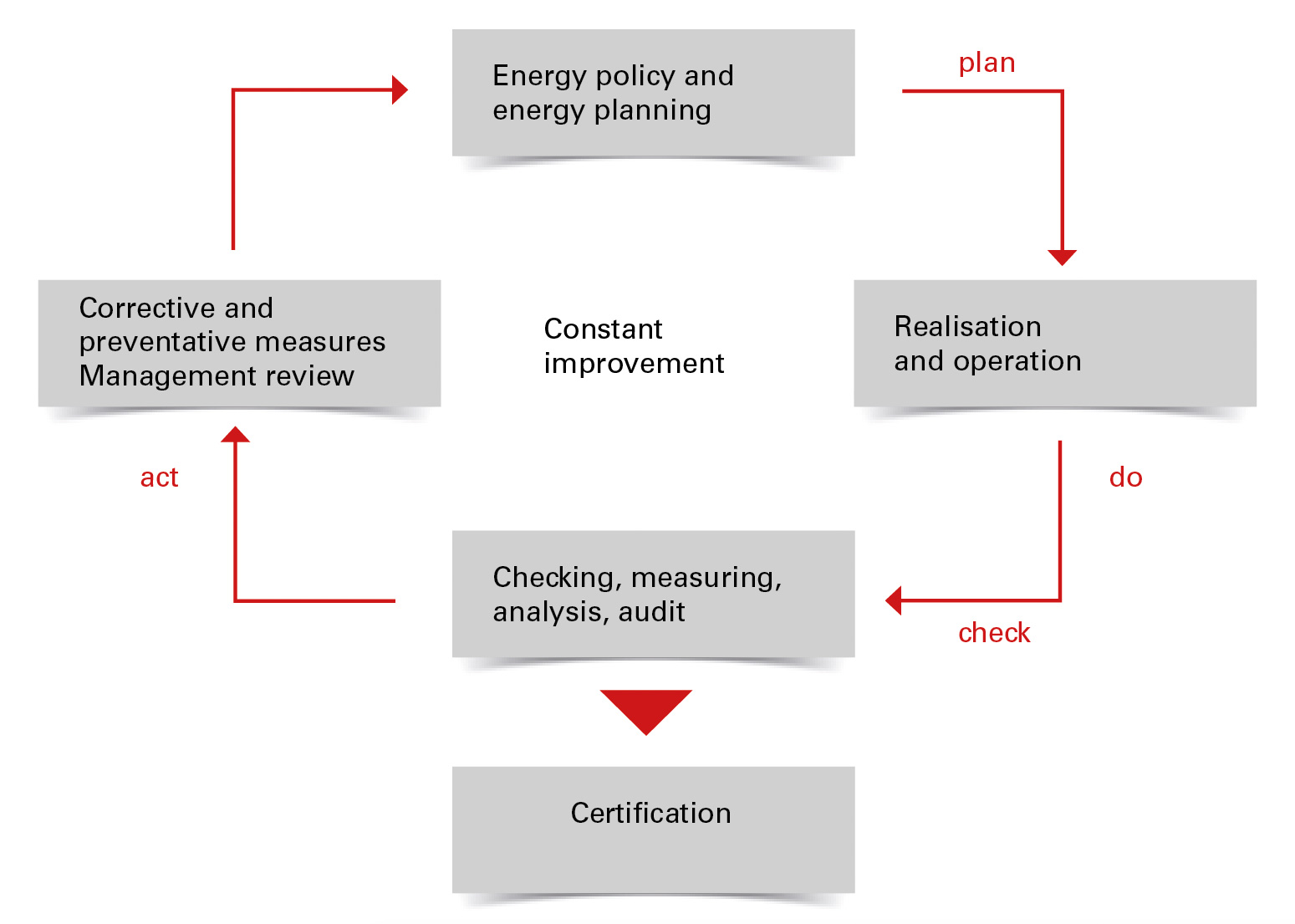

- From an annual consumption of 10 GWh, certification per ISO 50001 is required in order to request the reduction

The regulation is intended to secure the international competitiveness of energy- intensive companies. Due to the increase in the proportion of renewable energy generators, the EEG levy is likely to continue rising considerably. This means a significant competitive disadvantage for energy-intensive companies. Despite all the half-truths being touted by the media, in practice it is apparent that the lion's share of all companies who have applied for the EEG reduction and received approval for this are actually amongst the most energy-intensive companies and are in international competition. A significantly greater proportion of companies with a high power consumption of > 1 GWh per year fell at the first hurdle of the approval process, with the 14 % gross value added requirement.

You can receive applications and information from the main customs office responsible: www.zoll.de

Electricity tax law § 10 – surplus settlement

Under certain conditions, companies in the manufacturing sector are able to benefit from the so-called surplus settlement according to § 10 StromStG. This allows companies to obtain a reimbursement or tax relief against their remaining tax burden, through the application of § 9b StromStG.This "relief in special cases" (surplus settlement) is only granted if the tax burden exceeds € 1,000 in the calendar year (excess/basic amount).The rate of relief is dependent on the difference between the energy tax, which exceeds the basic amount, and the (notional) relief, which is derived on the basis that pension contributions have fallen since the introduction of energy tax (general pension contribution was 20.3 % prior to the introduction of energy tax and now stands at 18.9 %; with an employer contribution of 50 % this means a reduction of 0.7 % for the employer in 2013; the "difference"). A maximum 90 % of this difference is granted as relief, reimbursed or credited. This calculation formula leads to companies with a high power consumption and few employees (subject to statutory pension contributions) profiting in particular from the surplus settlement.

Since 2013 large companies require a certified energy management system per ISO 50001 in order to request the surplus settlement. For small and medium- sized companies (SME) an energy audit per DIN EN 16247-1 is sufficient.

In practice:

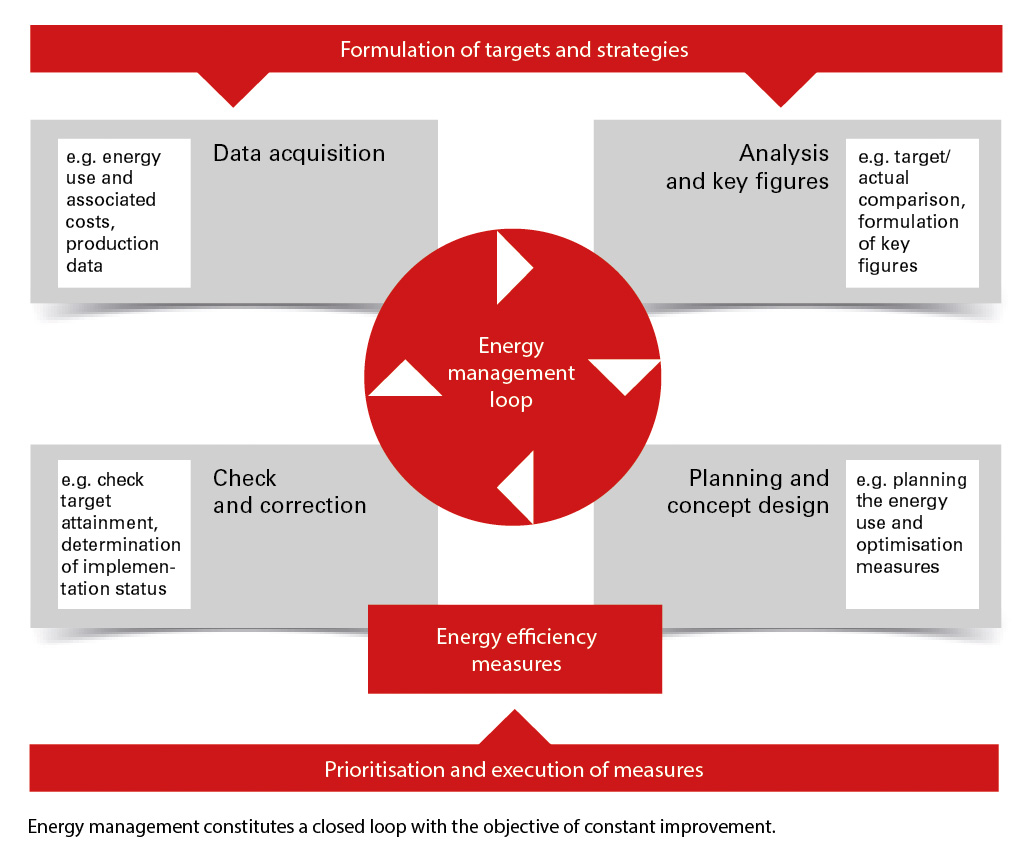

Managing director F. to works manager A.: "How much current do we actually use?" Works manager A.: "Not entirely sure, certainly a lot!" Managing director F.: "Be sure to change that!" Works manager A. to site electrician M.: "We need to reduce our energy costs. Take care of it." One year later. Managing director F. to works manager A.: "The energy bills are as high as ever. How is that possible?" Works manager A.: "I need to ask M. that." Works manager A. to site electrician M.: "We are still paying crazy energy bills. How is that possible? I told you that you needed to sort that out!" Site electrician M.: "Yes boss. But the controller cancelled the cash for new drives, then my colleague was ill for four weeks and you know that day-to-day work is hectic, the telephone rings constantly and everyone wants something!"

... with ISO 50001 that would not have happened!