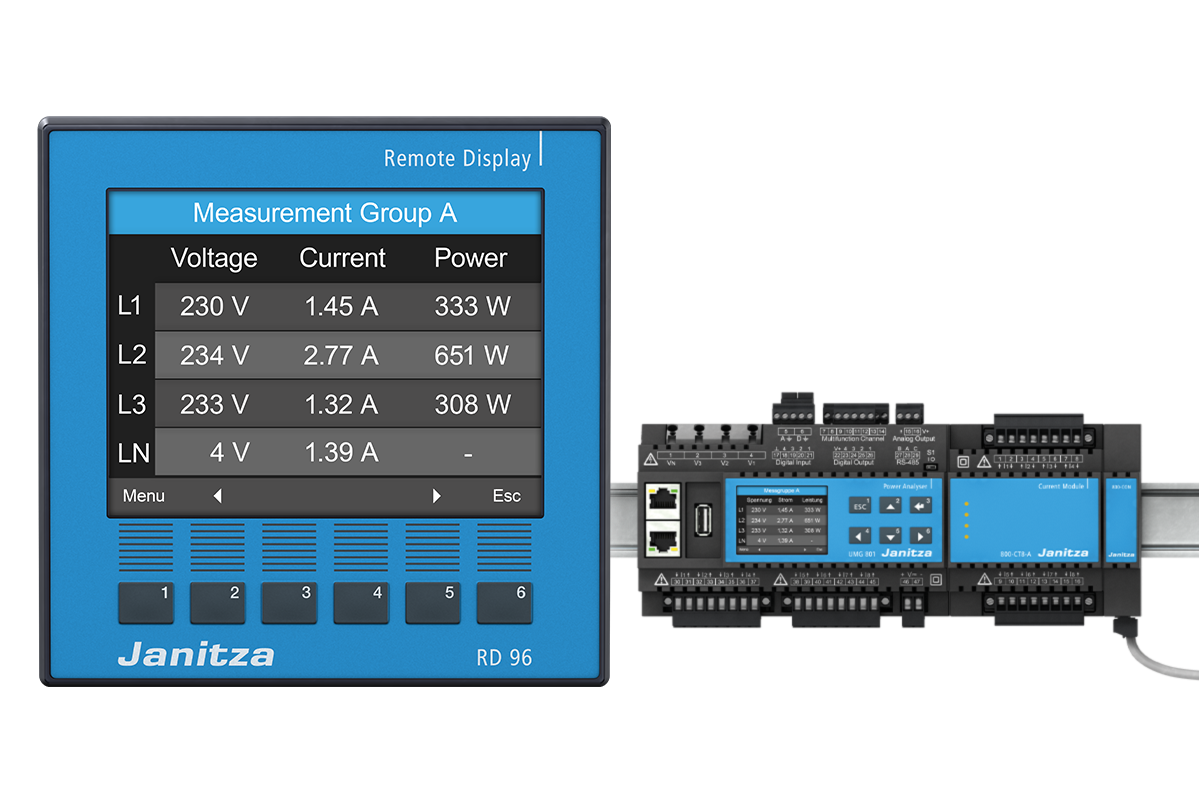

Modular Power Analyzer

-

-

GridVis®

Energy management, power quality, ground fault monitoring (RCM):

visualizing, analyzing, alerting, reporting

-

UMG 96-PA

Four functions - one solution - modular expansion

Energy management, MID, power quality monitoring and RCM monitoring