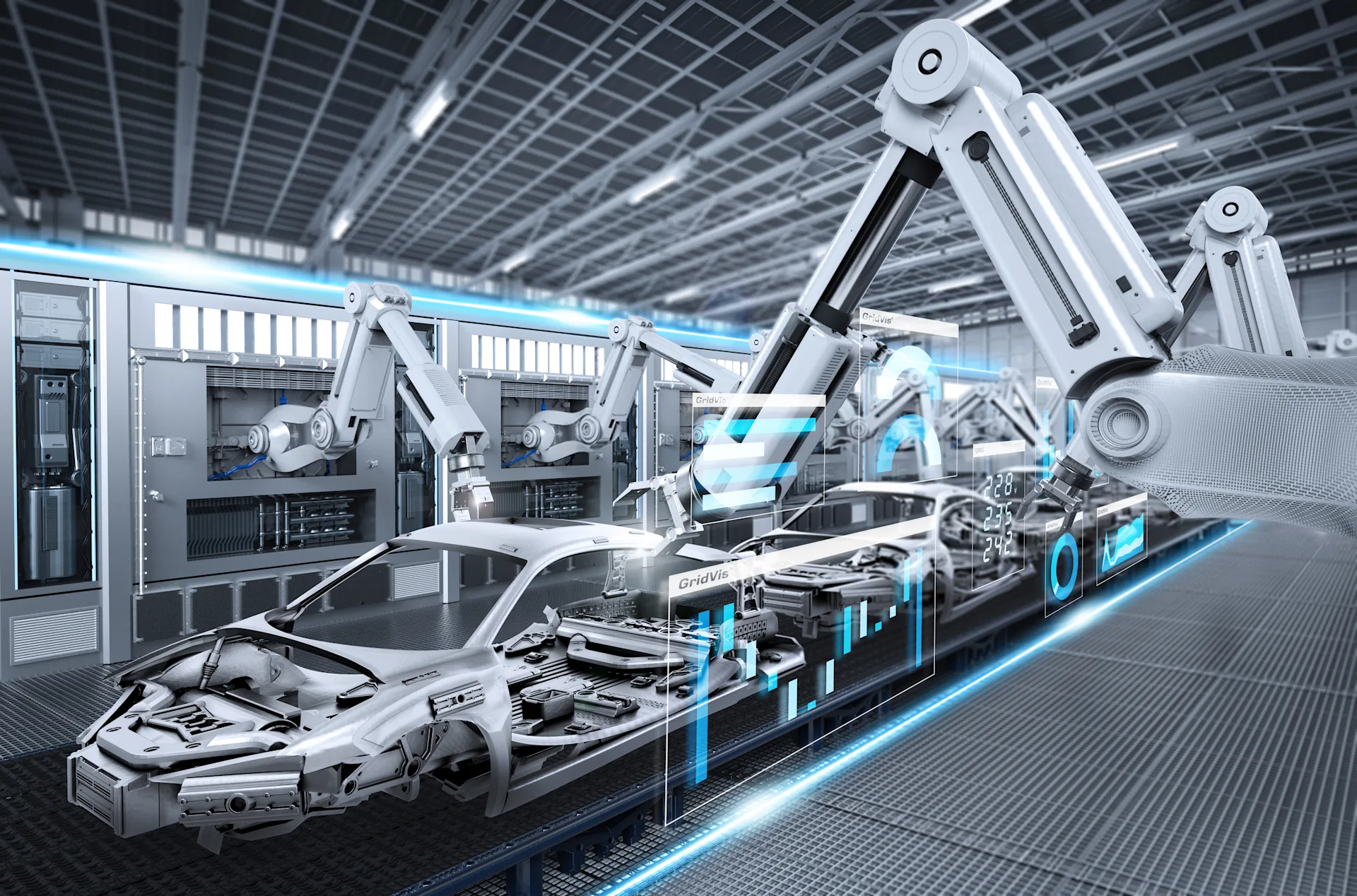

EFFICIENT AND HIGHLY AVAILABLE VEHICLE PRODUCTION

In the highly competitive automotive industry, innovation, cost efficiency, and sustainability must work together seamlessly. The more complex and energy-intensive the production process, the more crucial precise measurement technology becomes: for efficient energy usage, equipment protection, and smooth operation.

Keep an eye on your power consumption and grid quality at all times – for maximum efficiency and full regulatory compliance!

Challenges in the automotive industry

High availability of machines and systems

- A stable power supply is essential in highly automated automotive production. Voltage dips, harmonics, or transients can lead to production interruptions in welding systems, paint shops, or assembly lines, damage sensitive machines, or impair the quality of the manufactured products.

- In addition, power electronic consumers such as frequency converters, robotics systems, and UPS systems can cause complex grid reactions that remain undetected without continuous monitoring.

Production reliability

- In modern production environments with a high degree of IT and automation, insidious insulation faults can be overlooked because conventional residual current devices (RCDs) often intervene too late. The risk: fire damage, unexpected shutdowns, or costly production downtime.

- In addition, regulations such as IEC 60204-1 require regular insulation tests, which can often only be carried out when the system is shut down, leading to interruptions in production.

Energy efficiency and cost reduction

- Production facilities, such as pressing plants, paint shops, or engine manufacturing plants, consume a great amount of power.

- Transparency regarding energy flows is necessary in order to identify and implement potential savings.

Sustainability and carbon footprint

- OEMs and suppliers are under increasing pressure to produce in a carbon-neutral manner and disclose their carbon footprint.

- Regulatory requirements such as ISO 50001, ESG criteria, and the Corporate Sustainability Reporting Directive (CSRD) require accurate energy and emissions data.

Digitalization and data integration

- Different systems (SCADA, energy management systems) must work together based on data.

- Measurement data must be collected and analyzed in real time and integrated into existing IT systems.

Complexity and Internationality of the plants

- Many automotive manufacturers operate multiple plants around the world with different standards and infrastructures. Scalable and uniform solutions are needed to efficiently control processes worldwide.

- The automotive industry is making great efforts to secure its internal power supply. This includes wind turbines on factory premises and the installation of BESS storage systems from second-life batteries. This once again underlines the importanceof monitoring.

Power failure in automotive production plant

Losses of up to €50,000 per minute

An unexpected power outage can have dramatic consequences in the automotive industry. The average cost per minute of production downtime is between €25,000 and €50,000 – due to lost vehicle production, idle costs, and IT infrastructure disruptions.

The incident

In the 2010s, a large-scale power outage occurred at a German car manufacturer's plant, triggered by a malfunction in the company's own power plant.

The consequences:

- Production halt for several hours

- Shift workers laid off

- International website and email traffic down

- Disruption to neighboring district

The production of several hundred vehicles came to a standstill – with considerable economic losses.

The solution: early warning systems and grid monitoring

Continuous monitoring of the power supply allows potential disruptions to be detected and avoided at an early stage. Modern monitoring systems offer:

- Real-time data on grid quality

- Automated alerts when threshold values are exceeded

- Integration into energy management systems in accordance with ISO 50001

Conclusion

This example shows how important a reliable energy infrastructure is for automotive production.

Monitoring solutions can play a crucial role in preventing outages and reducing costs.

For energy-efficient, stable, and sustainable battery production

Battery production, as a central component of electromobility, requires not only maximum process reliability, but also maximum energy efficiency and sustainable operational management. Janitza provides the measurement technology basis for this.

New challenges in e-mobility production

The transition to electric vehicles has been fundamentally changing the requirements in automotive manufacturing. New production processes, higher power requirements, and growing demands for supply security and quality have presented companies with new challenges.:

- Significantly higher electrical power requirements, e.g., due to battery installation, charging infrastructure, or cooling technology

- Specific testing processes, such as high-voltage (HV) tests, require a precise and reliable power supply

- Increased demand for power quality and system availability in order to reliably manufacture sensitive components

Power supply requirements in the production of electric vehicles:

- Highly powerful (for HV manufacturing and testing)

- Fail-safe and redundant design

- Voltage-stable and continuously monitored

- Specially secured for high-voltage processes

- Sustainable and smart grid-compatible

Intelligent energy management

Reliable measurement technology and intelligent energy management create the necessary transparency and form the basis for safe, efficient, and future-proof production.

Janitza supports your company:

- Optimization of energy flows and avoidance of peak loads permanently reduces operating costs

- Avoidance of production downtime through continuous monitoring and early warning when threshold values are exceeded

- Permanent fault current monitoring protects systems and prevents costly failures

- Transparent recording of emissions and consumption data to meet ESG and ISO standards

- Modular system architecture that grows with production volumes, plant technology, and new requirements

Greater safety. Less energy loss. Full control – SOLUTIONS with Janitza measurement technology

With Janitza, you can lay the foundation for stable, efficient, and sustainable manufacturing – intelligently networked, measurably powerful, and ready for tomorrow's requirements.

Avoid unplanned downtime

Detect voltage dips, harmonics, or transients early on with precise power quality monitoring directly at critical equipment.

Increase production safety

Use continuous residual current monitoring (RCM) to prevent fires at an early stage and reliably avoid unplanned downtime.

Janitza's intelligent power analyzers support informed decisions for optimizing energy consumption and ensure compliance with standards such as IEC 61000-2-4 and IEEE 519.

Reduce energy consumption

Lower your energy costs through complete transparency of consumption at the plant, department, or machine level. Our solutions are ISO 50001 certified. Achieve up to 30% energy savings by controlling base load costs, operating load costs, and peak load costs.

Making sustainability measurable

Provide reliable data for carbon balances and ESG reporting – and comply with regulatory requirements such as the CSRD. Janitza measurement technology supports you in recording Scope 1 and Scope 2 emissions. In projects, all meters (including gas, water, heat, steam) can be implemented and all consumption data can be recorded continuously – for a comprehensive overview of resource usage.

Would you like to know how Janitza measurement technology can help you reduce your carbon footprint?

Implementing global standards

Whether for individual machines or global corporations: our scalable systems can be used worldwide and seamlessly integrated into existing infrastructures (Modbus, OPC UA, BACnet).

Everything at a glance with GridVis®

Our energy management software links all measurement data, visualizes key figures, and generates automatic reports, from live data to event analysis.

Suitable products

Get personal advice now

Your request is important to us and we guarantee fast and professional processing.