Technical details

Item no.: see product variants

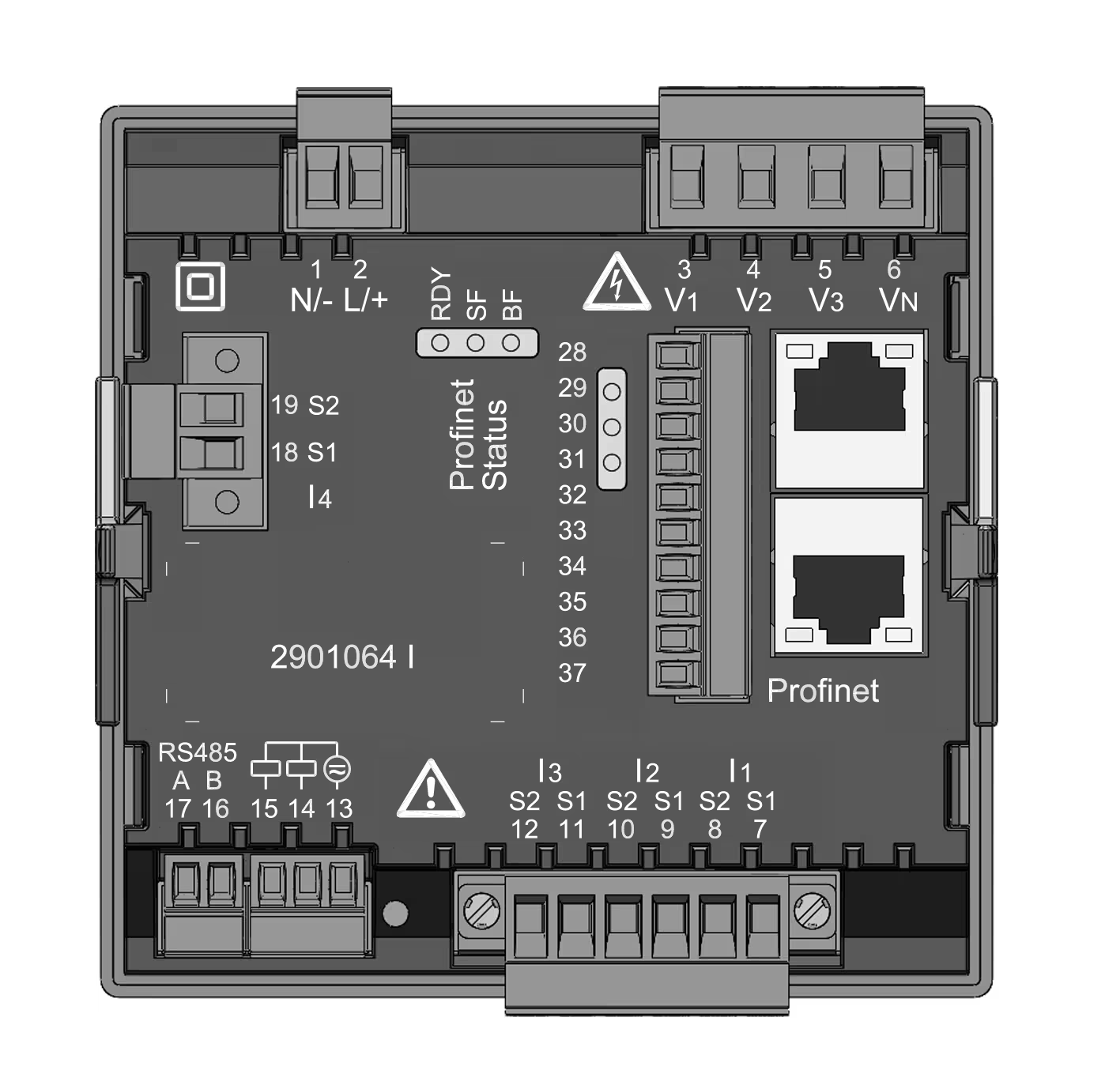

Drawings

Data at a glance

Certifications

- productCertifications.ul

Residual current inputs

2Harmonics V / A

1st – 40thActive energy class

0.5S (…/5 A)Digital inputs

*Digital / Pulse output

* / 2 pulse outputsInterfaces

- RS485

- Ethernet

Protocols

- productProtocols.modbusRTU

- productProtocols.profinet

Product variants

Functions and features

Stromkanäle

- Strommesskanal Phase L1

- Strommesskanal Phase L2

- Strommesskanal Phase L3

- Strommesskanal Neutralleiter (N messen / Überlastung)

- 2 x RCM (wahlweise Temperatureingang)

Schnittstellen

- 2 PROFINET-konforme Ethernetschnittstellen und integrierter Switch zum Aufbau von Linientopologien

- Zusätzliche RS485-Schnittstelle

- 2 digitale Ausgänge (Impulsausgang, Schaltausgang, Grenzwertausgang, Logikausgang)

- Zusätzlich 3 digitale Ein-/Ausgänge

Rest-Schnittstellen

- Software-Schnittstelle zur Abfrage von Messwerten und Konfigurationsparametern über HTTP-Protokoll, z.B. zur Einbindung der Messdaten in übergeordnete Softwarelösungen (GLT, SPS, SCADA,...)

- Maschine-Maschine-Kommunikation durch einfaches Architektur-Modell

RCM (Differenzstrom)

- Brand- und Geräteschutz

- Anlagensicherheit

- Erfüllung von Vorschriften

- Identifizierung von Isolationsfehlern

- Anlagenverfügbarkeit sichern

Webserver

- Echtzeit-Darstellung der aktuellen Leistungs-/ Strom- und Spannungswerte über die Gerätehomepage

- Gerätehomepage jederzeit über den Browser abrufbar

- Darstellung der Online-Messwerte

Gridvis®

- Visualisierung und Auswertung der Messwerte

- Einfache Erstellung von Reporten

- Aufbau von Energiemanagement-Systemen nach ISO 50001