Technical details

Item no.: 1401625

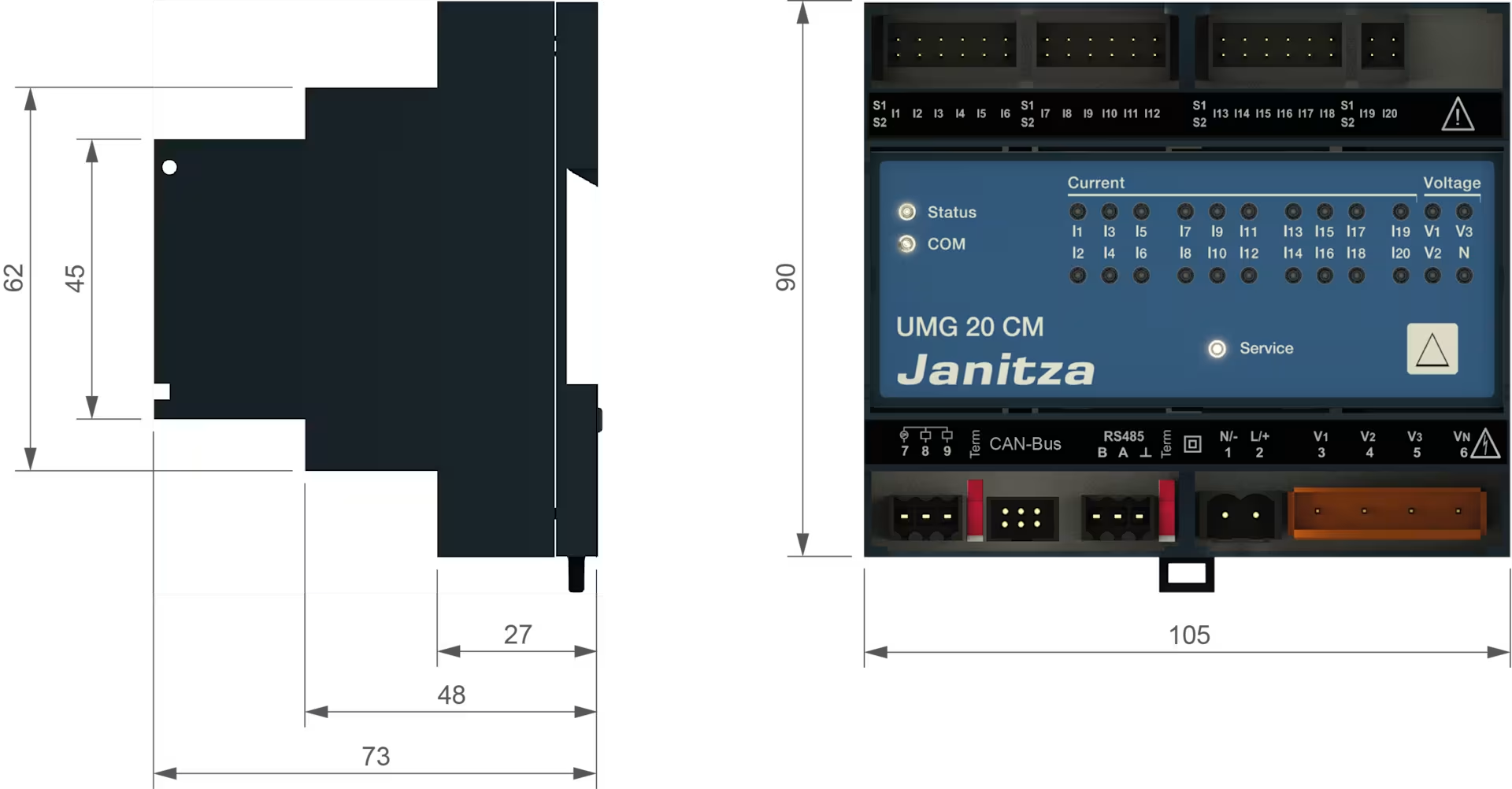

Drawings

Data at a glance

Supply voltage AC

Supply voltage DC

Harmonics V / A

1st – 63rdActive energy class

1Digital / Pulse output

2Memory size

768 KBInterfaces

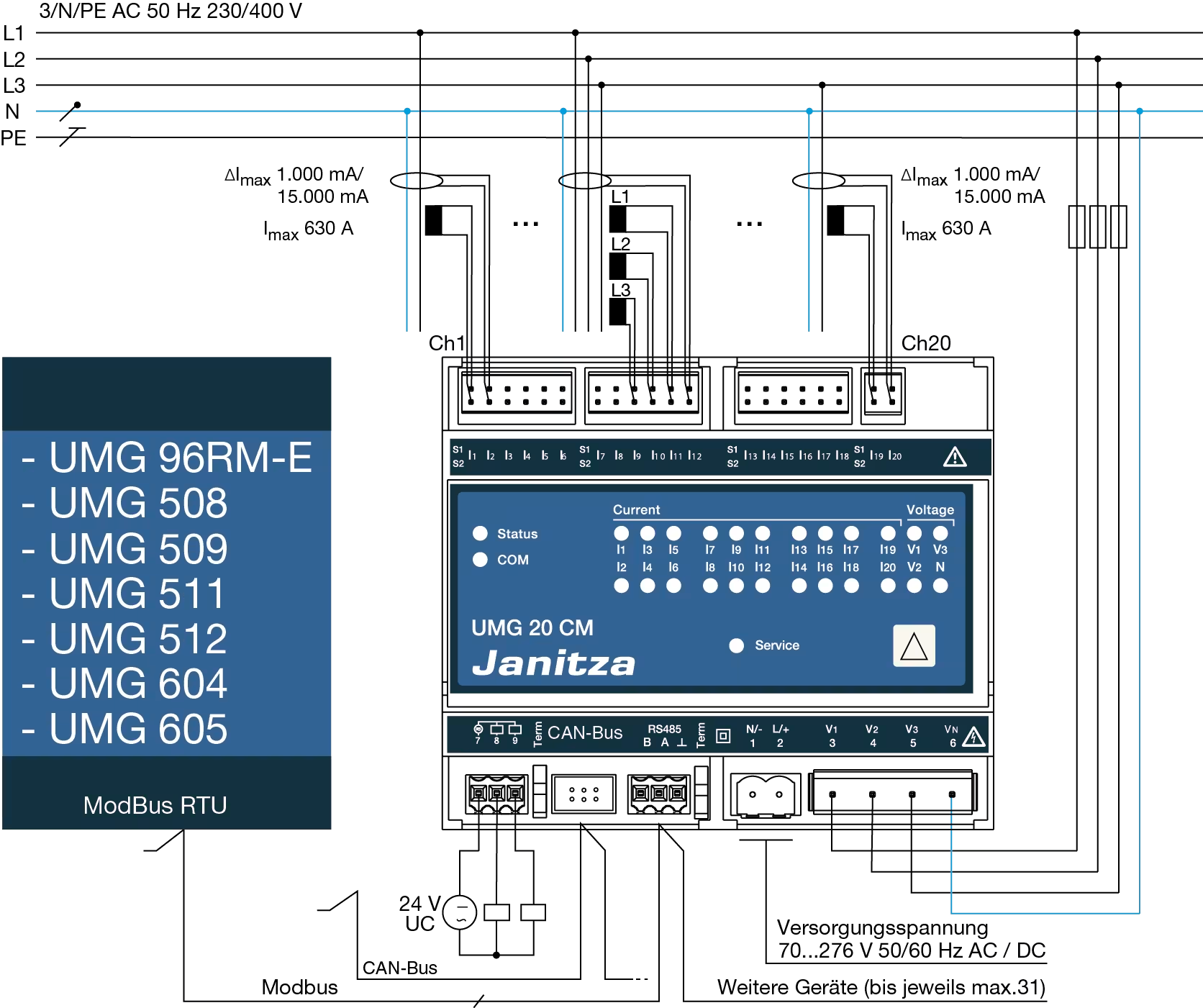

- RS485

Protocols

- productProtocols.modbusRTU

Functions and features

RCM and energy measurement device in one

- 20 current measuring channels

- 4 voltage measurement channels

- Internal RS485 interface (Modbus as slave)

- 20 LEDs – one LED for each current channel (green = OK, yellow = warning, red = rated current is exceeded)

- Measuring range with load up to 63 A with closed or separable current transformers (standard measured values: V, A, kW, kVA, kVar, kWh)

The system for smart minds

- Compactness of the system

- Can be retrofitted into existing systems

- Modbus RTU directly on board

- Status display per channel (LEDs)

- Name stored in measurement device per channel

- Wide-range power supply (90 - 264V AC / 120 - 240V DC)

- Integration into GridVis® software

- Various transformer types for individual applications

- Measurement variants:

- Three-phase and single-phase energy measurement

- RCM measurement with single and three-phase systems

- High sampling rate 20,000 Hz

- Transformer connection check (i.e. line breakage is detected)

- Harmonics analysis to the 63rd harmonic via the analysis channel

- Stores minimum and maximum values with timestamp

- Standard measured values: V, A, kW, kVA, kVar, kWh (variables list)

- Scalability of the system

Power supply without drop-outs

- Permanent monitoring and logging of processes in TN-S or TN-C-S systems

- Simple parameterisation and operation of the RCM measurement

- Automatic reporting in the event of problems enables a rapid initiation of countermeasures

- Comprehensive diagnostics increase safety and efficiency of a company

Alarms before failures (preventative residual current analysis)

- Faults arising will be detected in good time

- Monitoring, evaluation and reporting of creeping increases in residual currents (e.g. triggered by insulation faults and operating currents for system parts or loads being too high)

- Reduction of downtimes

Sensors for energy management

- Energy data of a large number of loads can be acquired and passed to a database with ease

- Automatic reading out and saving of the measured values and data saved in the measurement devices as well as the exceedance of parameterised threshold values

- Channel-specific measured values of the current monitoring devices can be displayed via the GridVis® software

- The evaluation and saving of data in central databases is implemented via the GridVis® software

- The greater the scope of information, the more accurate the determination of savings potentials

- Energy optimisation offers a higher, more economical savings potential (ISO 50001)

Your benefits - The intelligent system solution

- Early warning with system failures

- Avoidance of costly and hazardous system downtimes; the availability of systems is increased

- Localisation of individual faulty feeders, reduced work when troubleshooting

- Early detection of an overloading of the N conductor and critical residual currents, resulting in increased fire safety

- Through parameterisation of the system in new condition and constant monitoring, all changes to the system state after the point of commissioning can be detected

- Fulfilment of the safety criteria "RCM residual current monitoring" in data centres

- Convenient monitoring and parameterisation solution with GridVis® software

- Operating current acquisition of all relevant consumers as a basis for an energy management system (EnMS)