THE TRANSPARENT BREWERY

Project location

Meschede, Germany

Year of implementation

2024

Application

Power quality and energy analysis

Hardware

UMG 509 UMG 96RM-E, UMG 20CM

Software

GridVis® Expert

Service

Ethernet Modbus

REQUIREMENT

Veltins is one of the largest German breweries. Accurate operating data is essential for the continuous expansion and modernization of the production facilities, especially in times of rising energy costs. To this end, the pulse inputs of the meters were initially fed to the production data acquisition system via PLC. This procedure was to be replaced by direct recording based on measurement devices with suitable interfaces. The requirements of the departments are diverse. While the electrical workshop is mainly concerned with safety, capacity planning and power quality parameters, the process control technology focuses on energy management and ISO 50001 certification.

SOLUTION

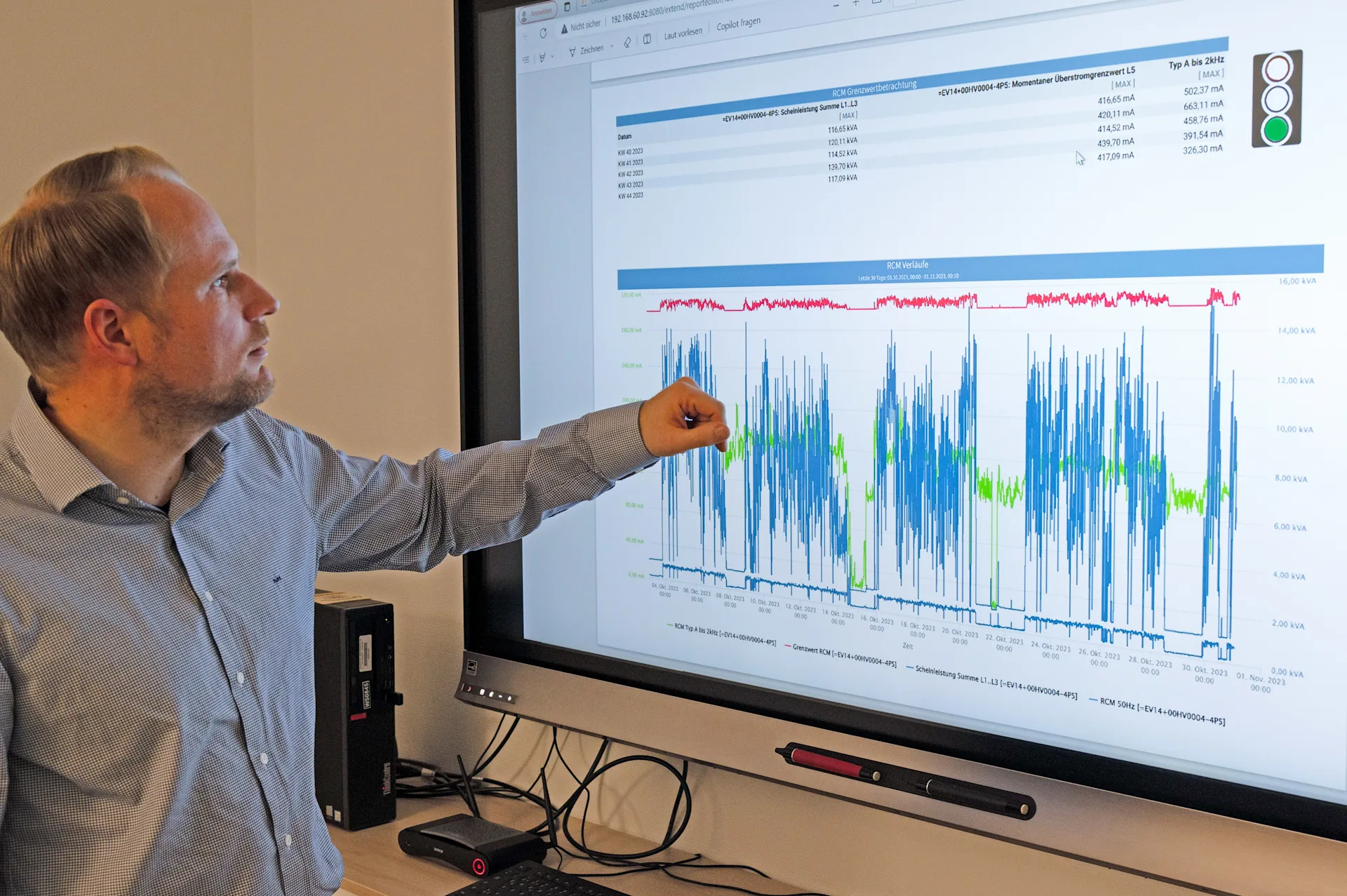

Initially, meters with pulse output were replaced by Janitza UMG 96S energy analyzers with Profibus interface, which were a good fit for the PLC infrastructure that was widespread in automation. With the installation of an Ethernet network, Veltins switched to direct recording via Modbus. There are now around 200 Janitza measurement devices in use. Two types are particularly common: The UMG 509 power analyzer for transformer feeds and for incoming goods monitoring of electrical energy. This allows short-term grid anomalies to be recorded and temporal correlations with production to be analyzed. It is complemented by the UMG 96RM-E multifunctional analyzer for larger outgoing circuits and systems. In addition to measuring energy in both directions, it also measures harmonics currents up to the 40th harmonic and residual currents, for example, and can seamlessly record load profiles for energy management systems such as ISO 50001. The UMG 20CM is used for many RCM measurements, e.g. for end consumers. It is capable of both energy data acquisition and residual current measurement. With 20 current measurement channels, it can record harmonics currents up to the 63rd harmonic. It can be expanded to up to 116 channels using additional modules.

BENEFIT

Veltins derives multiple benefits from the system, for example in terms of energy tax refunds. There are also key performance indicators (KPIs) that show the relationship between energy and production volume. This provides a precise insight into the plant, even into very complex processes. Thanks to open interfaces, the measurement devices can be used in several systems in parallel: Meter readings and active power are sent to the in-house PDA system, while the GridVis® can also be used to obtain other valuable data, for example on power quality. The measurement devices also enable residual current monitoring (RCM). This makes system monitoring much easier and also ensures greater safety. Above all, it makes the recurring insulation measurement in accordance with DGUV regulation 3 superfluous.